KIKUSUI PLZ-5WH2 Series DC Electronic Load

- Operating voltage: 10V to 1000V (Min. 1.5V)

- Power capacity: 1kW / 2kW / 4kW / 12kW / 20kW(5 models)

- 100 kW/ 2000 A with parallel operation (Max. 5 units), connectable with different models.

- LAN (LXI Compliant) / USB / RS232C standard interface *GPIB optional

- Synchronized operation / Sequence function

- Arbitrary IV characteristic (ARB) mode

Ideal for high-capacity power supply and rechargeable battery evaluation! Testing with hyper-realistic load simulation made possible!

The PLZ-5WH2 high power DC electronic load ser ies is where durable, reliable ingenuity meets multifunctional and high power design. Providing 5 variety of power range line-ups, from 1 kW bench top style model to high power model that can sink up to 20kW of power in a single unit. Possible to easily selects applicable power range depends on the load. Load simulation can be achieved faster than ever before thanks to the reliable, high speed design of the PLZ-5WH current control circuits. Accurate current measures can be made with extremely high setting resolution. A color LCD display allows for highly visible, user- friendly front panel operation. RS232C, USB, and LAN digital interfaces are included as standard for simple integration into any system.

Features

Arbitrary I-V Characteristics (ARB) Mode

In ARB mode, arbitrary I-V characteristics can be set by registering multiple I-V characteristic points (pairs of voltage and current values). Three up to 100 points can be registered, and the space between two points is linearly interpolated. The minimum voltage (0.00V) and current (0.00A) and the maximum voltage (1010.00V) are fixed.

Operation Modes

The following five operation modes are available on the PLZ-5WH2. In addition, available to set in operation modes other than CV mode, the “UVPL*” setting keep the voltage less than UVP setting by controlling the current and the “UVPT” setting loads off by applying a current to reach the target setting voltage.*”UVPL” is the “+CV mode” in PLZ-5W series

| Constant current (CC) mode | When a current value is specified, the current is kept at that value even when the voltage changes. |

| Constant resistance (CR) mode | When a conductance value is specified, the product sinks current proportio- nal to the voltage variation by using the value as a proportionality constant. |

| Constant voltage (CV) mode | When a voltage value is specified, the product runs the current so that the voltage is kept at that value. |

| Constant power (CP) mode | When a power value is specified, the product runs the current so that the power is kept at that value. |

| Arbitrary I-V characteristics (ARB) mode | The desired load characteristics can be set by specifying multiple arbitrary voltage values and current values as I-V characteristics. |

Maximum Slew Rate of 20A/μs

The PLZ-5WH2 series boasts a 20 μs rise time*, easily satisfying the critical needs of power supply evaluation tests demanding a fast transient response. *When using the PLZ20005WH2

Wide Ranging Operation Voltage up to 1000V

Operating voltage ranges from 10V to 1000V. Minimum operating voltage required to sink current is 1.5V.

Parallel Operation

Up to 100kW with parallel operation (Max. 5 units)

Parallel operation (max. 5 units) is available on all models by simply connecting an optional parallel operation cable. This feature is available even among different models for a wide range of high power. (up to 100kW / 2000A)*A parallel cable needs to have each unit connection. 12kW and 20kW models are included in accessory. 1kW, 2kW and 4kW models are option.

Parallel connection with PLZ-5WH series*

Must be PLZ-5WH as a Master and update the firmware to newest version. *When parallel operation between 5WH and 5WH2, only same capacity model is available.

| Model | Parallel operation number | Maximum current | Maximum power |

| PLZ20005WH2 | 2 | 800A | 40kW |

| 3 | 1200A | 60kW | |

| 4 | 1600A | 80kW | |

| 5 | 2000A | 100kW | |

Load On/Off

The following load on/off settings are available in addition to standard operations that can be carefully adjusted to fit the needs of any test environment.

- Start with “load on” when power is turned on

- Display elapsed “load on” time

- Auto “load off” when time limit is reached

- Control “load on/off” with external controls such as relays

- “Load off” by specifying conditions (Cutoff function)

Cutoff Function

The cutoff function allows the user to enable load off once the elapsed time/voltage drop/integrated current/integrated power has been reached after load on. Multiple factors can be selected, with load off being implemented after the first requirement is met.

| Elapsed time | The load turns off when the elapsed time value reaches the specified value. |

| Voltage drop* | The load turns off when the voltmeter value reaches the specified value. |

| Integrated current | The load turns off when the ampere-hour meter value reaches the specified value. |

| Integrated power | The load turns off when the watt-hour meter value reaches the specified value. |

*Voltage drop cutoff operates in the same manner as UVPT of the UVP function. | |

Changing the Response Speed

Set the response speed for CV, CR, or ARB mode according to the DUT’s conditions and application.

| Item | Description | |

| Response | Voltage | Set the response speed for CV mode. Normal, Fast |

| Conductance | Set the response speed for CR mode. Normal, Fast | |

| ARB | Set the response speed for ARB mode. The value is the filter response time. Select OFF for no filter. OFF, 500 μs, 1 ms, 2 ms, 5 ms, 10 ms, 20 ms, 50 ms, 100 ms | |

Soft Start

Soft start is a function that controls the rise time of the load current. Soft start functions only when all the following conditions are met.

- The rise time of the soft start has been set.

- Load on state in constant current (CC) mode.

- There is an input that is equal to or exceeds the minimum operating condition, from the state where there is no input to the load input terminals.

If the load current rises sharply, the DUT output may become unstable or the DUT’s overcurrent protection circuit may be activated. In such situations, it is possible to make the load current to rise slowly only when the product is started.

| Operation mode | CC |

| Time setting range | 500 μs, 1 ms, 2 ms, 5 ms, 10 ms, 20 ms, 50 ms, 100 ms, or off |

Data Logging Function

The data logging function allows the user to log measurement values (current, voltage, power) in the internal memory, and display logged data on an LCD screen (Table) as a chart (Chart). By setting measurement recording conditions, you can control the timing that measurements are recorded

| Condition | Value | Description | |

| Trigger | ー | Set the measurement recording timing and the number of times to record measurements. | |

| Source | ー | Event (trigger source) that defines the measurement recording condition. Recording starts after the Initiate key is pressed and a trigger is received. | |

| Immediate | Pressing Initiate applies a trigger immediately. | ||

| BUS | Applies a trigger when a *TRG command is received from a PC or when the *TRG key on the front panel is pressed. | ||

| DIGITAL2* | Applies a trigger when a signal is received at pin 13 of the EXT CONT connector. | ||

| MSync | The trigger application timing is synced between PLZ-5WH2 that are synchronized | ||

| TALink | Applies a trigger when a step is executed if Generate is set to TALink in the sequence step settings | ||

| Load Off | Applies a trigger when the load is turned off. | ||

| Count | 1 to 65536 | The number of times to recorded measurements. | |

| Delay | 0 μs to 100s (resolution: 10μs) | The delay time from trigger application until measurement recording. | |

| Interval | Disable / Enable | Sets whether to insert an interval between recordings when Count is 2 or higher. | |

| Interval Time | 10μs to 3600s (resolution: 10μs) | Recording interval time when Interval is set to Enable. | |

| Sense Aperture | 10μs to 1s (resolution: 10μs) | Time period of each recording. The average over the time period is recorded. | |

*Only when Direction of Digital 2 is set to Input | |||

Integrated Data Function

Time elapsed, integrated current and integrated power can be logged. Logging (integration) can be coordinated to start/finish when the load turns on/off or during the start or end of a sequence. Logging can also be controlled arbitrarily.

| item | Value | Description |

| Integral Gate | – | Set the integrated data recording period. |

| None | Integrated data recording is started/stopped manually. | |

| Load On | Recording is started/stopped automatically in synchronization with load on/load off. Or, recording is started or stopped manually. | |

| Program Run | Recording is started/stopped automatically in synchronization with sequence execution start/stop. Or, recording is started or stopped manually. | |

| Reset | – | Selects the integrated data reset method. If the product is restarted, inte-grated data is reset. |

| Manual | Integrated data is reset when the Reset key is pressed. | |

| Auto | Integrated data is automatically reset before the start of recordings. Or, integrated data is reset when the Reset key is pressed. | |

Saving Measurement Data

Measurement data can be stored in CSV format to a USB memory device.

Pulse Function

Pulse function refers to the operation of executing two settings repetitively. It is suitable for transient response characteristics testing of large capacity power supplies and batteries. When the pulse operation is in progress, a trigger signal is output from the TRIG OUT connector on the front panel. You can set this regardless of whether the load is on or off. This function operates in CC and CR modes. The pulse amplitude is set with a value or a percentage of the load value.

When the pulse operation is in progress, a trigger signal is output for 10μs from the TRIG OUT connector on the front panel when the current amplitude changes from low (Depth) to high (Set) level.

| Operation mode | CC and CR | |

| Frequency setting range | 1.0Hz to 10.0kHz | |

| Frequency setting resolution* | 1Hz to 10Hz | 0.1Hz |

| 11Hz to 100Hz | 1Hz | |

| 110Hz to 1000Hz | 10Hz | |

| 1.1kHz to 10.0kHz | 0.1kHz | |

* (Reference) The resolution actually set in the device is period resolution △T = 1μs, | ||

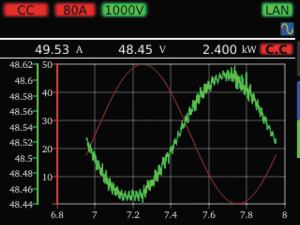

Sine Function

The sine function varies the current sinusoidally. It is suitable for super- posed ripple testing of large capacity power supplies and batteries. When a sine operation is in progress, a trigger signal is output from the TRIG OUT connector on the front panel. You can set this regardless of whether the load is on or off. This function operates in CC mode. You cannot set the slew rate. Set the sine amplitude with a value.

When a sine operation is in progress, a trigger signal is output for 10μs from the TRIG OUT connector on the front panel when the current passes through the Set value on the rising edge (sine wave phase at 0 degrees).

| Operation mode | CC | |

| Frequency setting range | 1Hz to 1kHz, 2kHz, 5kHz, 10kHz | |

| Frequency setting resolution* | 1Hz to 10 Hz | 1Hz |

| 20Hz to 100Hz | 10Hz | |

| 200Hz to 1000Hz | 100Hz | |

| 1000Hz to | 2kHz, 5kHz, 10kHz | |

* (Reference) The resolution actually set in the device is period resolution △T= 20μs, | ||

Sequence Function

A sequence consists of programs and steps. A program is a collection of steps. Steps are executed in order one at a time, star ting from step 1. The completion of the last step signifies that the program has been executed once. When the specified number of program loops is completed, the sequence ends. You can set the load state (load on or off, load value, slew rate) at the end of the sequence of a program.

| Setting range | Setting | Description |

| By step | Load value | Current, conductance, voltage, power. The values that can be set depend on the current operation mode. |

| Slew rate | Sets the speed of change when the current is changed. | |

| Step execution time | 0.000050 s to 3600000 s (50μs to 1000h), resolution: 1μs | |

| Load on/off control | To turn the load on, set the load setting transition method to step or ramp. | |

| Other | Trigger signal setting, trigger signal output | |

| For each program | Number of loops of program | 1 to 100000 repetitions, or infinite repetitions. |

| Protection function | Specifies the value at which a protection function (OCP, OPP, UVP) is activated. | |

TALink

The TALink (Transient Acquire Link) trigger makes it possible to log data in PLZ-5WH2 in synchronization with the sequence steps. Logged data can then be accessed through ommunication with the PLZ-5WH2 and saved to a USB as a CSV file./p>

Alarm Function

This function detects anomalies and protects the DUT. There are two types of alarm based on urgency level: alarm 1 (high urgency) and alarm 2 (low urgency).

Alarm 1 (high urgency)

| Name | Activation |

| Overvoltage detection (OVP) | Load off |

| Reverse-connection detection (Reverse) | |

| Overheat detection, overcurrent detection of the front-panel DC INPUT terminals (OTP/Front) | |

| Alarm input detection (External) | |

| Parallel operation anomaly detection | |

Alarm 2 (low urgency)

| Name | Mode | Activation |

| Overcurrent protection (OCP) | CR, CV, CP | Load off or limit |

| Overpower protection (OPP) | CC, CR, CV, ARB | |

| Undervoltage protection (UVP) | CC, CR, CP, ARB | Load off, limit, or activation off |

| Watchdog protection (WDP) | All | Load off |

This function limits the current (UVPL) or turns off the load (UVPT) when the voltage applied to the product becomes equal to or less than the UVP setting. You can set this regardless of whether the load is on or off.

| Trip | Turns the load off. The setting display changes to UVPT. |

| Limit | Limits the voltage so as not to become equal to or less than the set value. The setting display changes to UVPL. |

ABC Preset Memories

Three setting values can be stored in preset memory slots A, B, and C. All saved settings can be accessed at the press of a button, which is perfect for when you want to quickly switch between three sets of values.

Setup Memory

The setup memory can store up to 20 sets (0 to 19) of the current conditions of the items listed below. The current conditions can also be saved in a USB memory device.

- Operation mode

- Load values (current, voltage, conductance, power)

- Slew rate

- Pulse amplitude (current/conductance or percentage)

- Pulse interval (frequency/time of one cycle and duty cycle/operating time on the high side)

- Sine amplitude (current)

- Sine frequency

- Alarm operating conditions

- Content of ABC preset memories

A file saved on the PLZ-5WH2 can be transferred to the PLZ-5W via a USB memory device. If the UVP is set to “limit” on the PLZ-5WH2, this will be changed to +CV mode on the PLZ-5W (PLZ205W, PLZ405W, PLZ1205W).

External Control

The PLZ-5WH2 can be controlled and monitored from an external device. The external control terminals are isolated from the load input terminal.

Current and Voltage Monitor

In addition to the conventional current monitor output, voltage monitor output (0 V to 10 V/Output of 1/100 of measured voltage) has been added to the front BNC connector.

USB Keyboard

You can enter numbers/characters if you connect a keyboard to the USB port on the front panel. The types of keyboards that you can use are 101-key and 104-key keyboards.

Remote Sensing

With remote sensing, the voltage measurement point can be changed from the load input terminal to the DUT sensing point. By connecting the sensing leads to the DUT, the effects of voltage drops caused by resistance in the load cables can be reduced and the operation in CR / CV / CP / ARB mode stabilized. ● Remote sensing input rated voltage: 1000 V

Synchronized Operation

The following synchronization features are available when simply connecting the PLZ-5WH2 with other equipment using a communication cable. Any of the models in the PLZ-5WH2 series can be connected together. Synchronized operation is possible even during parallel operation.

- Synchronizing load on/off among multiple pieces of equipment

- Synchronizing measurements.

- ynchronizing the start time and resume time for sequences across multiple units.